Rattan, Wicker, and Cane: Understanding the Differences

Jan 26, 2026

The terminology of cane, wicker, rattan, and rush furniture can be confusing, so we thought it would be helpful to describe them and what the differences are. We sometimes get calls from customers asking if we can repair broken cane seats, and we have to answer their question by asking a question - "is it hand woven or sheet cane?" That starts the discussion with the customer and we'll explain why this is important later in this blog post.

Rattan Palm

Cane and rattan furniture is made from the rattan climbing palm, grown in tropical forests. Most commercial rattan is made in Southeast Asia. The rattan vine is typically harvested in the wild and then cut into:

- Strand Cane - thin strips cut from the outside bark of the rattan. It has a smooth, shiny, curved side to it.

- Flat Reed - thin strips cut from the inner bark of the rattan. It is flat on both sides and is not shiny. It is weaker and less durable compared to cane.

- Reed Spline - larger thickness of strips cut from the inner bark of the rattan

Wicker Furniture

Wicker refers to a style of weave, not a type of material. While wicker furniture can be woven from round pieces of rattan, reed, bamboo, or willow, round reed is the most common material used. This table has a wicker top with bamboo legs and stretchers. The legs are wrapped and joined to the stretchers with rattan (flat reed or binder cane). This is an example of a piece of furniture that can be referred to as either rattan furniture or wicker furniture.

The construction method for rattan furniture is very different than wood furniture. The joints of the parts are secured using cane. Here's a video showing the repair of rattan furniture joints:

There is also synthetic wicker furniture, made of resin or vinyl material, which is much more durable for outdoor use.

Cane Furniture

Cane is used in a number of ways on furniture, most commonly on chair seats. The traditional method of making cane seats was by hand weaving strand cane through holes in the seat frame. This is a long and tedious process. Hand weaving one seat can take 8-10 hours.

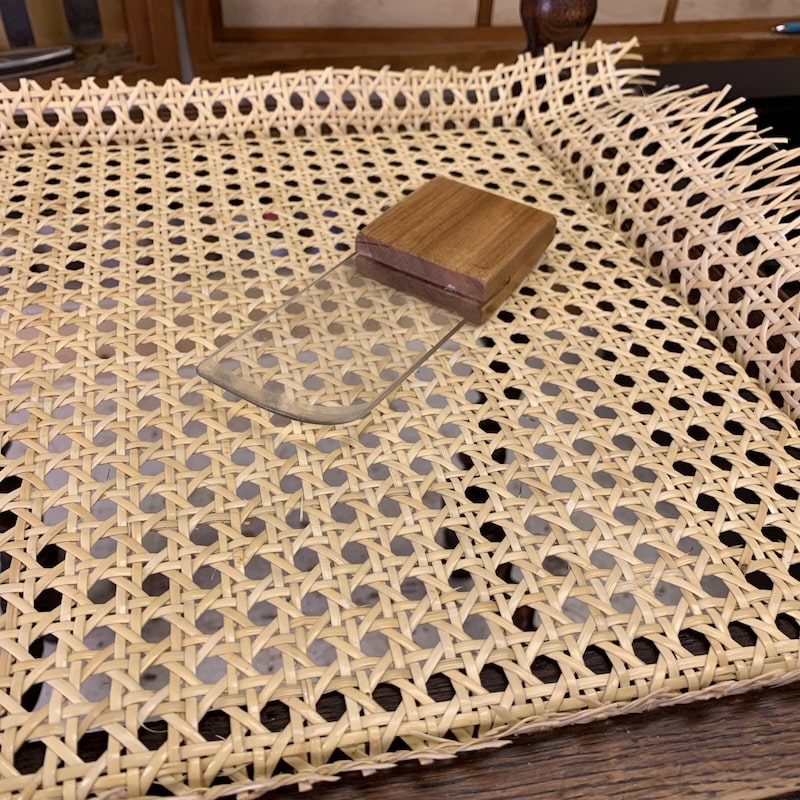

In the late 19th century, weaving machines were invented to weave cane sheets, also known as pre-woven cane webbing. Another innovation was cutting a groove in the furniture to install the cane webbing and secure it in place with glue and a reed spline. This became a much faster, affordable way to make cane furniture. A Cane Installation Tool makes cane webbing easier and faster to install. This is a more reliable way to gently install the cane webbing versus using wood wedges that can put stress on the wood frame and potentially break it.

Here's a video showing how to replace broken cane webbing:

Cane can be purchased in different forms:

- Pre-woven Cane Webbing or Sheet Cane is available in different weave patterns and sizes

- Strand Cane for hand-weaving. A hank (bundles of about 1,000 feet of cane) will weave about 4 square feet.

- Binding Cane is used for wrapping joints on rattan and wicker furniture. It is similar to strand cane but it is wider and thicker.

- Reed Spline in a wedge-shaped format specifically for cane webbing

- Round Reed for wicker weaving

Some other forms of woven seating are rush seating and Danish Cord seating.

Rush Seating

While this style of furniture is not popular, rush seating is another type of woven material used in furniture. Rush is a reedy march plant that is used to weave seats. The Rush is twisted together to make a rope. Natural rush is the traditional material and should be used when restoring antiques. Fiber rush is a strong paper-based material that is easier to use and looks similar to natural rush. This photo shows an example of a woven fibre rush seat.

Danish Cord Seating

With a renewed interest in mid-century modern furniture, danish cord is becoming more popular. This paper-based material is typically 3-ply and the natural colour is susceptible to getting stained by use over time. The danish cord is woven in various designs and is secured with L-shaped nails.

If you're interested in learning how to repair furniture, take a look at our furniture repair courses and our Fixing Furniture Community.

Author: Scott Bennett, Co-owner, Wooden It Be Nice - Furniture Repair

Stay connected with news and updates!

Join our mailing list to receive the latest news and updates from Fixing Furniture.